“I noticed a gap in the market for interesting cladding,” says Beren Yeshua, Managing Director of Scotland-based artisan cladding manufacturer Tiny Temple. Since 2021, Tiny Temple has worked to fill that gap from their mill near Edinburgh, where they produce cladding, decking and fencing in a variety of species, finishes and profiles.

“We work with a lot of different timbers,” Beren says, “including Scottish larch, Imbue (previously known as Abodo), Accoya, Canadian western red cedar, and frake noir. When we first started, we tried cutting Scottish larch logs ourselves but quickly realised that buying it cut and dried was a lot more efficient. So we bought and made machines for charring, brushing, sanding and painting the wood. Then we got a knife-grinding machine and started making our own profiles. Now, from CNC-cut templates, we can make any profile, size or colour of cladding.”

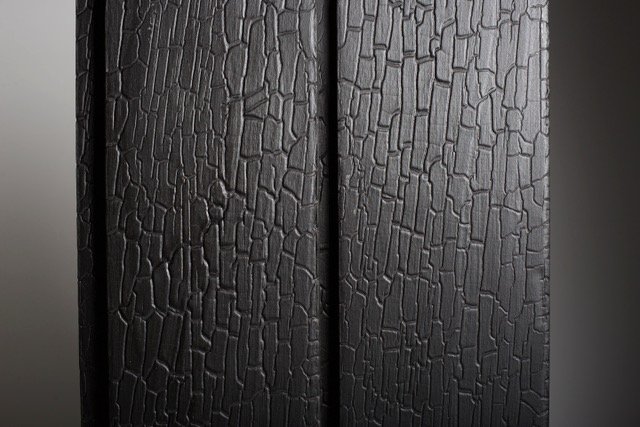

A highlight in the product line is Shou Sugi Ban, a Japanese charring technique that thermally treats timber, producing high-quality, durable, beautiful timbers for a range of applications, and of which Tiny Temple is the only Scottish manufacturer. “Shou Sugi Ban has a unique appearance that brings out the grain and texture of the wood. We either char the timber very deeply, giving it a desert, cracked, alligator effect, or we can char it and brush the char off, leaving an imprint in the wood. In addition to being visually striking, this technique makes the timber more durable without the use of any chemicals, increasing longevity, waterproof properties, and pest resistance.”

“There’s a lot of moisture to contend with here; if timber isn’t weatherproof or can’t dry out properly, it will rot pretty quickly. Our profile angles are designed to shed the water off right away.”

This increased performance can be especially beneficial in the Scottish climate, where rainy weather persists for much of the year. “There’s a lot of moisture to contend with here; if timber isn’t weatherproof or can’t dry out properly, it will rot pretty quickly. Our profiles are all designed with angles that shed water off right away.” There can also be a knowledge and expectations gap between architects and joiners with regards to product application and installation technique, Beren says - one which Tiny Temple is eager to bridge. “There’s a bit of a learning curve with modern timber cladding, with both architects and clients having a greater awareness of design and higher-end finishes than they did 20 or 30 years ago. This can create a discrepancy between the expectations of architects and the contractors who work with them.

“We are working to solve this by developing training and raising awareness around our products. We’re currently in the process of turning our show room into a learning centre where visitors can see every part of the product and the customer journey: from seeing our production in action to choosing the timber and finish to showing cutaway sections of how it’s installed. There are so many options now for how timber can be produced and used. We want to create an experience where people can visit us and choose their own adventure, like when you design your own sandwich in a sandwich shop.”

The food service comparison is apt for Beren, whose life before timber manufacturing had many chapters, including running a café and creperie. “I’ve always been interested in how things work and how they’re put together,” he reflects. “Mum says I used to take everything apart as a kid. I left school at 16 and started a gardening business where I would walk to customers’ houses and use their tools. From there, I created a landscape and garden maintenance business that I ran until I was about 20. I then planned to open a health food shop but, about a month before opening, that idea turned into a café and creperie - in homage to my dad’s French roots. I did that for a couple of years near Dundee and learned a lot about the trials and tribulations of running a business before moving into mobile catering and street food, doing weddings and also street food at Edinburgh Festival.”

It was through his meditation teacher that Beren finally found his path to architecture and design in 2018. “He noticed that I had a passion for woodworking and encouraged me to build a meditation hut in my garden, which became the first Tiny Temple. Then my friend asked me to build her one, and things sort of snowballed from there. I built a few more, but realised that I was a perfectionist, which made things quite slow. I had always thought producing cladding was beyond me, but I took a leap of faith and bought a 3.5-tonne, six-head planer from a liquidation auction. I didn’t know how to use it. I didn’t have anywhere to put it. I ended up storing it for a year in Penicuik until I found a farmer who was willing to let us rent a space in his shed. We’ve since taken over the whole 25,000-square-foot shed and are now preparing to buy it and the five acres surrounding it.”

While still a fairly young company in architecture industry terms, Tiny Temple has a number of projects completed and nearing completion, including a recent residence designed by Jones Robbins Architecture in Elie, Fife. “That project won Dundee Institute of Architects (DIA) Best Domestic Extension of the Year 2025. It required a very uniform cladding finish that wouldn’t need much maintenance. We used a SIOO:X silicate coating, which gave the cladding an even, consistent finish and turned out really nice. We’ve got another residential project underway with Brown and Brown Architects in the Highlands using this same coating which is on site now and due for completion later this year.”

Beren attributes Tiny Temple’s success to a LEAN manufacturing and production approach, where he and his small team work closely on continual improvement and optimisation. “A huge part of our approach is to work towards not making the same mistakes twice. We will stop and fix what bugs us - even if it’s laborious in the short term - so that we don’t continue to experience that challenge further down the track. We also produce everything in one line - bandsawing, charring, painting - rather than in individual bits. No one else does that, but we have found that approach enables us to make our production seamless. The fact that the first piece of wood goes through everyone’s hands before it’s complete means that any defects or quality issues are caught and rectified immediately and at the source..”

The team also benefits from a non-heirarchical approach, where every member is hands-on in multiple stages of the production and sale journey. “We don’t have an office team and a manufacturing team. All six of us are super involved at every stage of the process. For me, that means I get to experience and love every aspect: coming up with new products, designing unique profiles, making cladding that no one has seen before, streamlining production processes, and improving customer experience.”

Looking ahead to 2026 and beyond, Beren and his team are bringing tools and techniques in-house to enable them to go deeper into every part of the business. “We’re building our own machinery from scratch for our production, and we’re working with a software developer to build our own app for integrating every aspect of what we do. This will be used for calculating quotes, production planning, and inventory management. All our electricity is generated by renewable energy, but we’re going further to transform our sawdust and rejected cladding boards into briquettes for burning in domestic woodburners that we will sell. By continuing to optimise our efficiency by reducing waste of every type in our business, we’ve been able to double our turnover each year so far, but still managed to keep our lead time at two weeks.

“The goal is always to reduce struggle and find ways to produce a lot more with the team we already have. I want to create an experience that feels seamless for our customers and suppliers and continue to keep Tiny Temple a company that’s a joy to work with and for. I love that we can start by grinding a knife edge to 0.01mm accuracy that then machines thousands of metres of cladding, passing through everyone’s hands that works in the mill, and then seeing it wrapping a beautiful building. Tiny Temple is a night-and-day contrast to other kinds of work I’ve done that weren’t really my passion. I’m genuinely obsessed.”

To learn more and connect with Beren, visit https://www.tinytemple.co.uk/, follow him on LinkedIn, and check out Tiny Temple on Instagram.